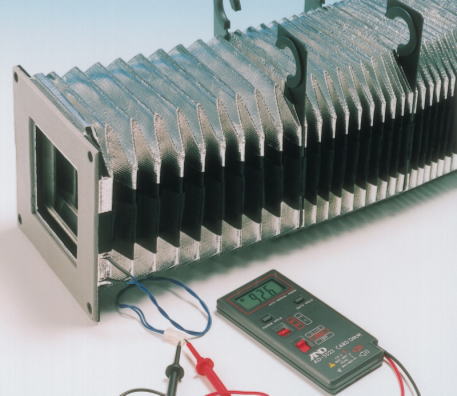

10. Bellows used in LASER beams path

Laser beams path

Since laser was discovered it has widely been used for cutting and welding metal and the world laser machine market is getting larger each year with over 5,000 units produced in 2005.

The laser processing machine unlike conventional machine tool requires the bellows that protects the path of laser beams.

Laser beams after generated by the laser oscillator reaches the processing point, reflected and redirected with mirrors. The laser processor, a metal welding machine, inevitably produces metal powder during the process, and if the powder stuck to the surface of the mirrors it would cause a problem. When laser beams hit the soiled surface it may get burnt causing heat strain, eventually making precise processing impossible. And it may also damage expensive optical devices including the lens.

Therefore, a cover or bellows is needed that protects the optical path by expanding and contracting along X, Y and Z axes and the bellows has to be inflammable against reflected beams. Such characteristics are needed here as being tightly shut, dust-proof and inflammable.

The protective bellows belongs to the same category as the bellows of cameras since it secures light paths. It is an indispensable bellows for optoelectronics.

Let us then take a look at the bellows inside of which passes a fluid (gas, liquid and solid matter) or it stands the use in a vacuum.